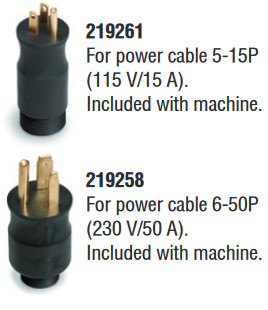

MVP – Multi-Voltage Plug – allows connecting to 230V or 115V with no tools required.

Processes GMAW (MIG), Flux Cored Flux Cored (FCAW)

I really like it because you can use it at 115v and later expand from a shed to a workshop with larger service. And when you upgrade to 230V, you still retain the 110 portability. Besides, in my opinion, running welder from 240 will often make a great difference, 120V is in most cases a poor circuit to weld from.

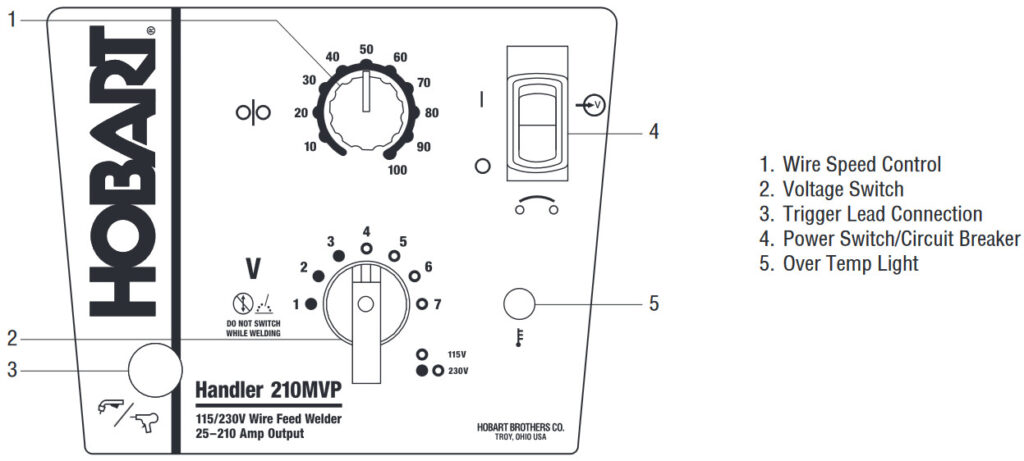

The HH 210 MVP offers 7 taps (output voltages) and stepless speed controller for wire feed. So unit is easy to adjust for different thicknesses, wires and materials.

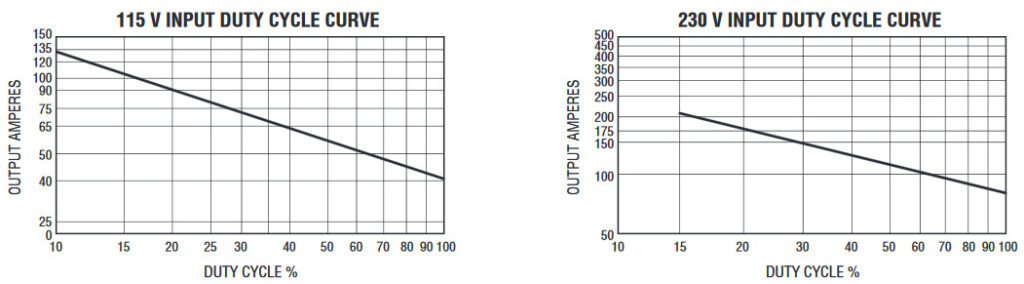

For 115V HH210MVP utilizes 4 voltage taps and 140A of weld output. For 230V – 210 amps of output and All 7 taps.

Pay attention that HH 210 is relatively heavy and not so easy to carry (net weight 79 lb) and 12-3/8in(H), 10-5/8in(W), 19-1/2in (D). I have to “grab and growl” when pick one. On the other hand, a light duty cart is all that’s needed to move it around the shop.

210MVP has much better (see the picture below) duty cycle and makes good single passes on 3/16″ and C25 gas. The lightweight ground cable and lightweight MIG gun may hinder the “210 amp” output.

More power is always better. You always can turn down the settings but if you don’t have the amps, you won’t be able to turn it up.

You can bought a spoolgun for aluminum that will easily burn holes in 3/16″ aluminum. It has 10 ft cable. Rated 150 amps, Includes carrying case and shipped with .030 in. and .035 in. contact tips.

Apply a tiny bit of silicone to the o-rings before assembly to ease seating the power pin and help avoid cutting an o-ring. The unit will make better welds.

Check out this video: