In welding, portability is a huge factor for many of us. Getting the welder to where the work needs to be done is essential, whether it’s on the other side of the garage or the other side of town. The demand for portability is what has made the Miller AutoArc XLT142 Portable MIG Welder a go-to welder in a wide variety of settings.

It’s a compact, portable welder that has the power to accomplish a diverse assortment of large and small welds on steel and aluminum. At just 73 pounds and with its compact dimensions, the XLT142 gives you greater access to work areas beneath equipment or up on scaffolding. And when you get to the job you’ll have the functionality you want to fix or fabricate whatever you need.

The Miller AutoArc XLT142 Portable MIG Welder, or Miller MLL907263, is a flux-cored wire and MIG welder that uses reliable constant-voltage DC power. It features an onboard gas solenoid and a dual-gauge regulator and gas hose. The rugged and steady onboard feeder delivers the wire you need from 40-700 IPM under load or 50-740 without load. It does all this with 115 volt power that makes it extremely versatile, a welder you can take just about anywhere there’s 115 volt power on a 20 amp circuit.

Miller AutoArc XLT142 Details

This welder is outfitted with the tools you need to get your welding done efficiently and precisely. The 10-foot H10 model MIG torch gives you excellent reach as does the 10-foot lead and clamp. The kit includes 3 contact tips at .030 along with a starter 1 pound spool of .030 flux-cored welding wire. You also get a welding set up chart which takes the guesswork out of customizing every weld. Quickly adjust the power and arc and you are ready to turn out another perfect weld, with capacity up to ¼”.

Warranty Information

Miller Electric stands behind the AutoArc XLT142 with one of the best warranties in the industry. It is a 5-year comprehensive warranty that covers anything and everything. You don’t find that every day in the welding business.

The Miller AutoArc XLT142 Portable MIG Welder, or Miller MLL907263, is a flux-cored wire and MIG welder that uses reliable constant-voltage DC power. It features an onboard gas solenoid and a dual-gauge regulator and gas hose. The rugged and steady onboard feeder delivers the wire you need from 40-700 IPM under load or 50-740 without load. It does all this with 115 volt power that makes it extremely versatile, a welder you can take just about anywhere there’s 115 volt power on a 20 amp circuit.

WHO USES THE MILLERMATIC AUTOARC XLT142 MIG WELDER?

The 115V functionality along with the portable size and weight makes this a popular choice wherever welding needs to be done. While not designed for heavy industrial use, it’s got the guts to tackle any weld up to ¼”, and that covers a lot of ground. You’ll find it cranking out the work in home garages and shops, light to medium industrial settings, fab shops, auto-body garages, hot rod and bike shops, maintenance garages, farms, ranches and more.

At just 73 pounds, it is also a good choice for contractors who want a welder they can take with them to the job site when the occasional weld is required on the project or a piece of equipment needs repair. Rental shops often have a Miller AutoArc XLT142 on hand as a rental unit because of its versatility and ease of use. When you want an easy-to-use, high-performance MIG/flux-cored welder this one deserves serious consideration.

Summary:

- Miller AutoArc XLT142 Portable MIG Welder

- Part number: MLL907263

- Flux core and MIG processes

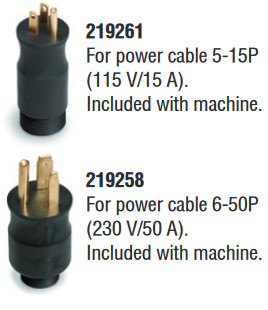

- Corded 115V plug

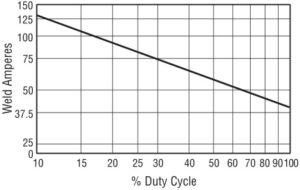

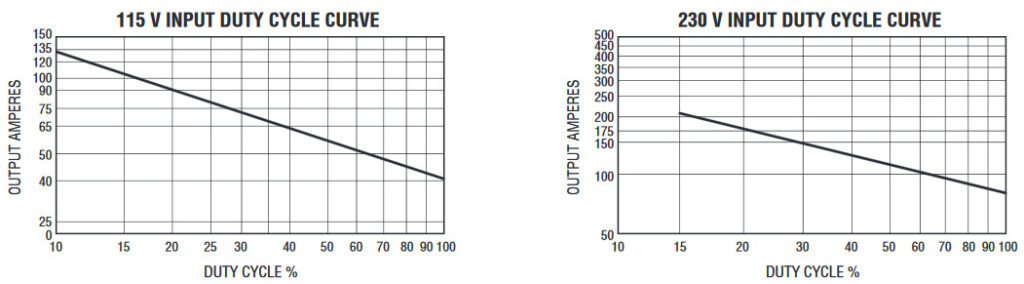

- Rated 90A output with 19VDC at 20% Duty Cycle

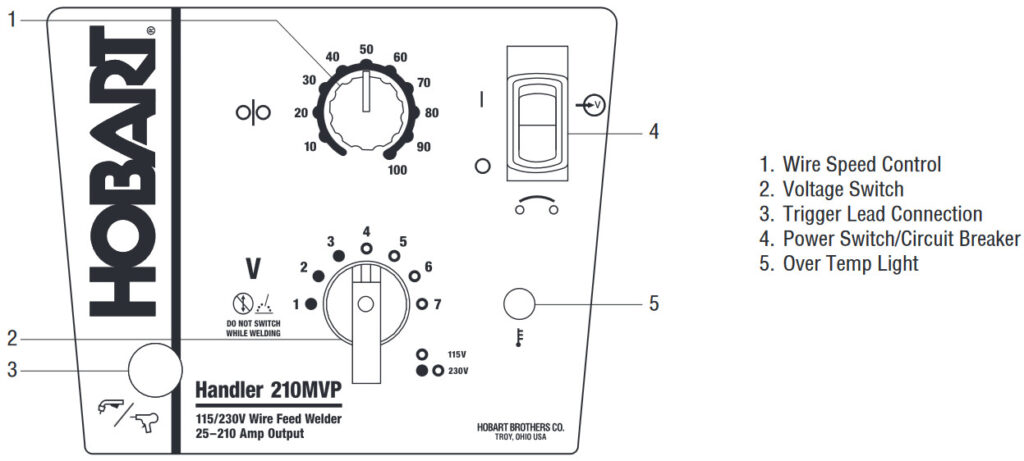

- 25-140 amp range with multiple settings for total control

- Adjustable, continuous wire feed: 40-700 IPM (load), 50-740 IPM (no load)

- Wire diameter to .030 inches

- 10-foot MIG torch

- 10-foot work cable

- Handy setup/Info chart

- Weight: 72.6 lbs

- Made in the U.S.A.

Before jumping right into the welding tips it is important that everyone reading this understands that there are different types of stainless steel and they are not all welded the same. There are in fact three classes of the product we call stainless steel. There is also a mixed class called Duplex, and it is recognized by their metallurgical structure, to be more precise by their microstructure. They are Ferric, Austenitic, Duplex and Matrensic.

Before jumping right into the welding tips it is important that everyone reading this understands that there are different types of stainless steel and they are not all welded the same. There are in fact three classes of the product we call stainless steel. There is also a mixed class called Duplex, and it is recognized by their metallurgical structure, to be more precise by their microstructure. They are Ferric, Austenitic, Duplex and Matrensic.